USA ヘンプ・ミュージアム

館長から皆さまへ

館長から皆さまへ ヘンプの歴史

ヘンプの歴史 ヘンプと農業

ヘンプと農業 ヘンプの医療と健康

ヘンプの医療と健康 ヘンプ食品

ヘンプ食品 ヘンプ織物

ヘンプ織物 ヘンプ縄と糸

ヘンプ縄と糸 ヘンプパルプ紙

ヘンプパルプ紙 ヘンプ建材

ヘンプ建材 ヘンプ燃料

ヘンプ燃料 ヘンプ原料

ヘンプ原料 ヘンプ溶剤

ヘンプ溶剤  ヘンプ・プラスチック

ヘンプ・プラスチック ヘンプ・プラスチック

ヘンプ・プラスチック フォード・プラスチック・カー

フォード・プラスチック・カー 自家製プラスチック

自家製プラスチック  ヘンプと環境

ヘンプと環境 ヘンプと娯楽と精神世界

ヘンプと娯楽と精神世界 ヘンプと法律

ヘンプと法律 ヘンプと政治

ヘンプと政治 ヘンプ貢献者

ヘンプ貢献者 ミュージアム図書館

ミュージアム図書館 Topに戻る

Topに戻る |

|

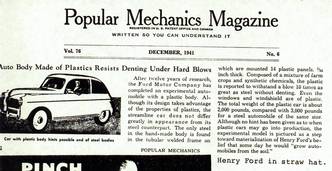

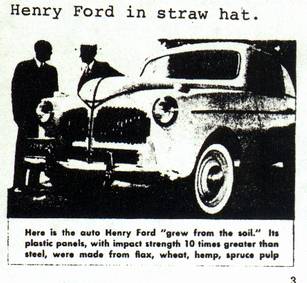

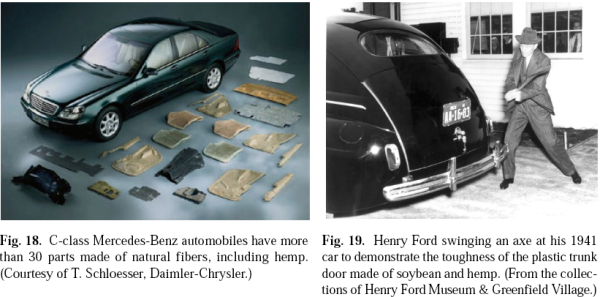

Figure out a way to use agricultural products in industrial manufacturing, and everyone would benefit. He put his chemists to work determining what products could be developed from plants. After testing numerous crop plants, they narrowed their focus to soybeans. Experimentation was soon rewarded with the discovery of soybean oil which made a superior auto body enamel. Soybean meal was converted to plastic used to make over 20 parts including horn buttons and gearshift knobs. By 1936, Ford was using a bushel of soybeans in every car that rolled off the line. But Henry Ford didn't stop there. While his chefs developed a variety of tasty and nutritious American-style foods from soy (including ice cream) Henry invented soybean "wool", a fiber half the cost of sheep's wool. Soon a fabric containing 25% soybean wool was being used to upholster many Ford autos. And on special occasions Mr. Ford would sport a suit made of soybean fiber. - Our thanks to Bill Shurtleff, Soyfoods Center. On a White Wave carton as pictured at left. There is of course the rest of the Henry Ford story. He didn't stop with a few car parts, Ford predicted that he would some day "grow automobiles from the soil." Which he did after 12 years of research. From Popular Mechanics, 1941, Vol. 76, No. 6, December, 1941. Title: Auto Body Made of Plastics Resists Denting Under Hard Blows.

Composed of a mixture of farm crops and synthetic chemicals, the plastic is reported to withstand a blow 10 times as great as steel without denting. Even the Windows and windshield are of plastic. The total weight of the plastic car is about 2,000 pounds, compared with 3,000 pounds for a steel automobile of the same size. Although no hint has been given as to when plastic cars may go into production, the experimental model is pictured as a step toward materialization of Henry Ford's belief that some day he would "grow automobiles from the soil." "When Henry Ford recently unveiled his plastic car, result of 12 years of research, he have the world a glimpse of the automobile of tomorrow, its tough panels molded under hydraulic pressure of 1,500 pounds per square inch from a recipe that calls for 70 percent of cellulose fibers from wheat straw, hemp, and sisal plus 30 percent resin binder. The only steel in the car is its tubular welded frame. The plastic car weighs a ton, 1,000 pounds lighter than a comparable steel car. Manufacturers are already talking of a low-priced plastic car to test the public's taste by 1943."

|